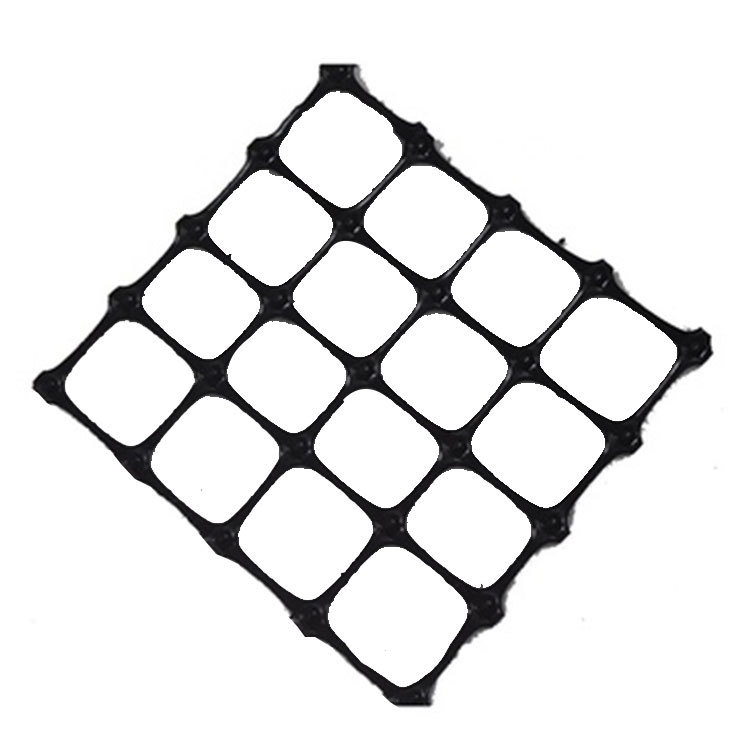

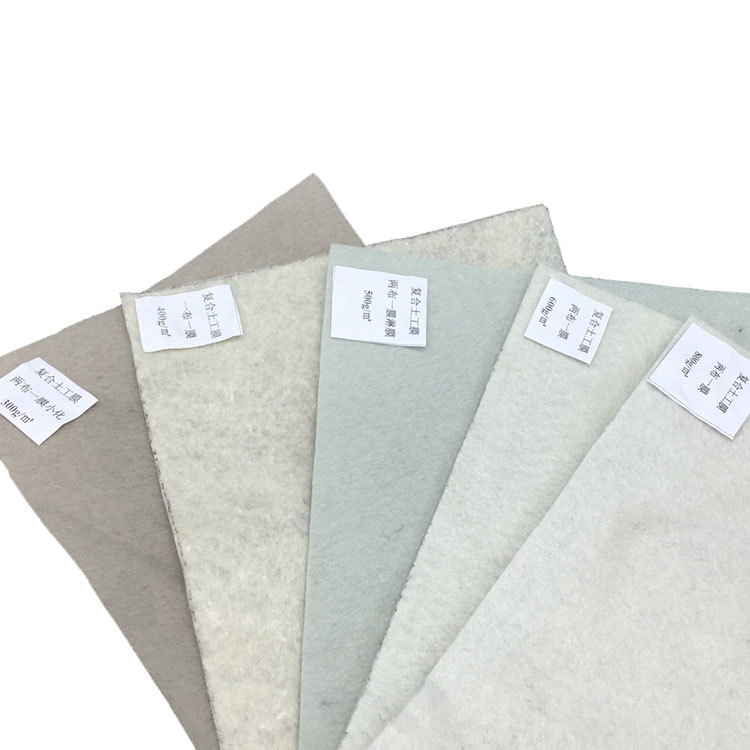

Composite Geosynthetics Net Drainage Network for Drainage Layer Geonet Geomat 1200g-1500g

- Commodity name: Composite Geosynthetics Net Drainage Network for Drainage Layer Geonet Geomat 1200g-1500g

- Description

-

Introduction

Three dimensional composites drainage network is a new type of drainage geotextile material. It is one three-dimension geonet composited with two needle-punched non-woven geotextiles. Three dimensional composites drainage network consists of a tri-dimension thick vertical rib, and a inclined rip on the top and bottom. Double sided adhesive seepage geotextiles form a "filtration - drainage - ventilation - protection" overall performance, and can replace the traditional sand and gravel. Its pore maintenance system can drain underground water quickly, block the capillary water under high load in construction, keep certain thickness and provide good water conductivity property. At the same time, it can also play the role of isolation and foundation reinforcement. Mainly used in railway, highway, tunnel, municipal engineering, reservoir, slope protection and other drainage works, and the effect is remarkable.

Video Showcase

Applications

- Highways: vertical edge-of-carriageway drains intercept the lateral flow of ground water. Modern fin drains reduce excavation, reduce backfill quantities and reduce installation time. In-slope drainage increases geotechnical stability.

- Retaining walls and bridge abutments: to reduce pore water pressure and avoid backfill saturation.

- Engineered landfills: with the additional requirement of long-term chemical resistance and high compressive strength.

- Tunnels: ground-water-seepage interception between rock face and the tunnel lining.

- Buried structures: vertical and horizontal drains for basements, culverts, car parks, reservoirs, etc.

Working Drawing

Specifications

Pack and Ship

Packaging: Standard packaging or customer's requirements

Lead time: Within 10-15 days after receiving the deposit payment

Producing Capacity: Two 40ft Containers per week

Testing equipment

FAQ

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Certificate

Keywords:

Related Products