Warp-Knitting Reinforced Composite Fiberglass Geogrid Nonwoven for Concrete Road Surface

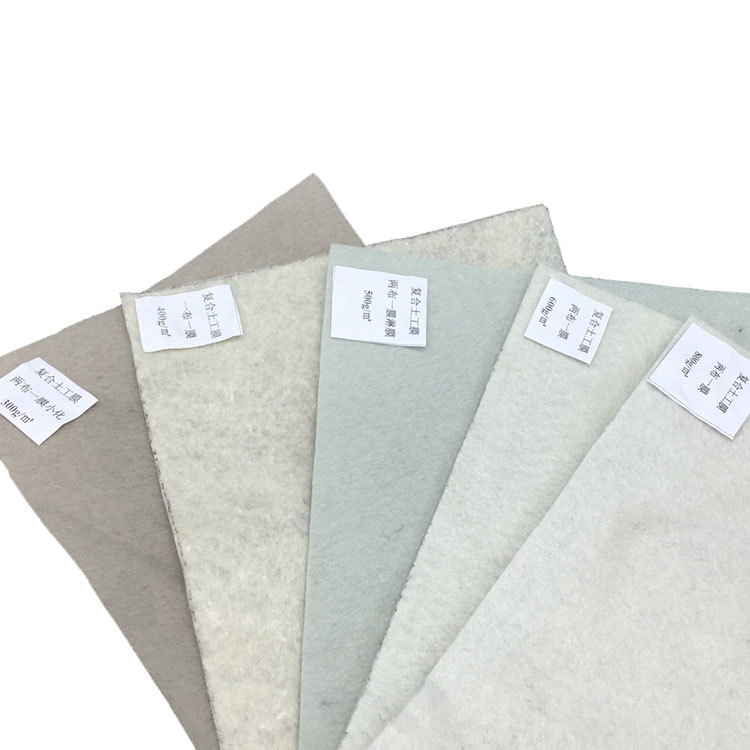

- Commodity name: Warp-Knitting Reinforced Composite Fiberglass Geogrid Nonwoven for Concrete Road Surface

- Description

-

Introduction

Geogrid composite is a composite of fiberglass geogrid, polyester geogrid and plastic geogrid mixed with non-woven geotextile or cloth thru adhesive and warm melting methods. The non woven geotextile surface is hard and no longer effortless to slide all through the construction. It allows the strengthened geogrid composite remain clean in the system of paving. It is a form of modern composite geosynthetic materials, which natural combining the extraordinary overall performance of geogrid and geotextile. This product can be designed in accordance to real requirement.

Besides, we can additionally sew the geogrid and geotextile collectively which is extra secure shape below outdoor force.Applications

- Multifunctionality: Composite geogrids are composed of a number sorts of geosynthetic substances and have more than one functions, such as tensile strength, permeability resistance, erosion resistance, etc. The aggregate of unique layer substances makes it appropriate for distinct engineering wants and can gain more than one useful requirements.

- High electricity and stability: Composite geogrids have excessive electricity and balance thru the aggregate of multi-layer structures, which can successfully beautify the bearing potential and deformation resistance of the soil, and lengthen the carrier lifestyles of the project.

- Durability and climate resistance: composite geogrid generally has corrosion resistance, getting old resistance, put on resistance and different characteristics, can be used stably for a lengthy time beneath one of a kind environmental conditions, and has accurate sturdiness and climate resistance.

- Environmental safety and economy: Composite geogrid substances are generally made of environmentally pleasant materials, which have proper environmental performance. At the equal time, its diagram is reasonable, development is simple, can shop manpower and cloth resources, enhance building efficiency, and has a sure diploma of economy.

- Multi area application: Composite geogrids are broadly used in street engineering, water conservancy engineering, environmental engineering, mining administration and different fields. It can be used in a range of kinds of tasks such as reinforcing roadbeds, defending waterways, stabilizing slopes, and stopping geological disasters.

Working Drawing

Specifications

Pack and Ship

Packaging: Standard packaging or customer's requirements

Lead time: Within 10-15 days after receiving the deposit payment

Producing Capacity: Two 40ft Containers per week

Testing equipment

FAQ

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Certificate

Keywords:

Related Products