Plastic Dimple Drainage Board Composite Geotextile for Green Roof

- Commodity name: Plastic Dimple Drainage Board Composite Geotextile for Green Roof

- Description

-

Introduction

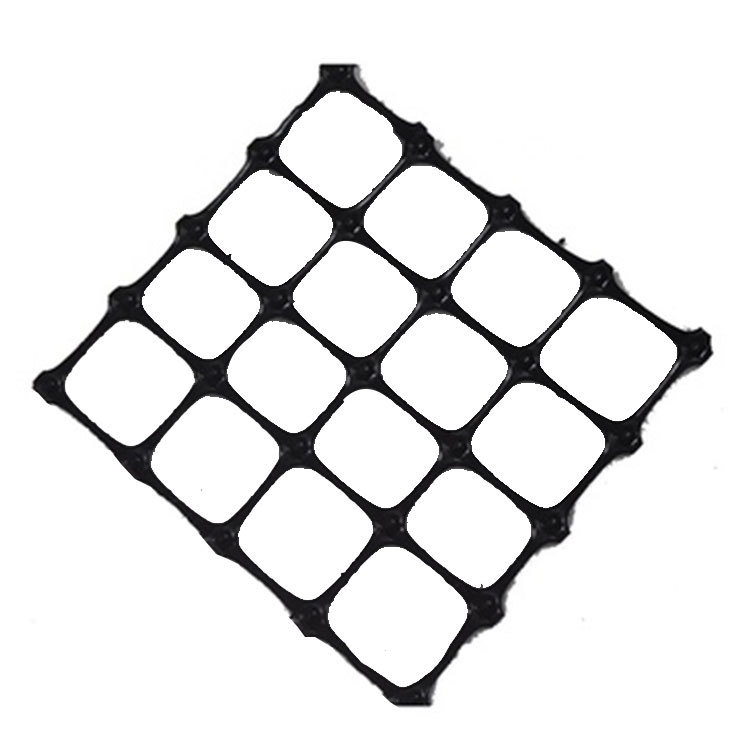

The water storage and drainage board is made of polyethylene plastic injection molding. It is a new kind of drainage fabric that integrates drainage and water storage functions. It additionally has a couple of features such as water storage, drainage, ventilation, insulation, and root resistance (preventing plant roots from destructive concrete structures). When mixed with geotextiles, it can stop great particle matrix from blockading water storage tanks and drainage channels, keep clean drainage and air circulation, and shape a entire and new kind of water storage and drainage system, which is extensively used in city landscaping projects.

Video Showcase

Working Drawing

After the building of the water-resistant layer and its shielding layer is completed, begin laying the drainage board. Require the slope of grassroots drainage to meet a vary of two ‰ to 5 ‰;

2. Lay the drainage board with the cup formed mouth going through upwards and the tooth interlocked;

3. Cover the drainage board with geotextile, overlapping 10-20cm to forestall mud and water from passing via the geotextile, clogging the water storage and drainage system, inflicting terrible drainage and decreased water storage capacity;

4. Lay 10-20mm medium coarse sand on the geotextile to structure a permeable filter layer, which can forestall the loss of planting soil;

5. Cover with gorgeous thickness of planting soil.

6. It is critical to make sure the safety of completed drainage boards. After the installation of the drainage board, it ought to no longer be allowed to at once push hand carts on the drainage board. When transporting materials, timber boards and horse paths ought to be laid. Ensure that the soil is crammed as quickly as it is laid.Specifications

Pack and Ship

Packaging: Standard packaging or customer's requirements

Lead time: Within 10-15 days after receiving the deposit payment

Producing Capacity: Two 40ft Containers per week

Testing equipment

FAQ

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Certificate

Keywords:

Related Products