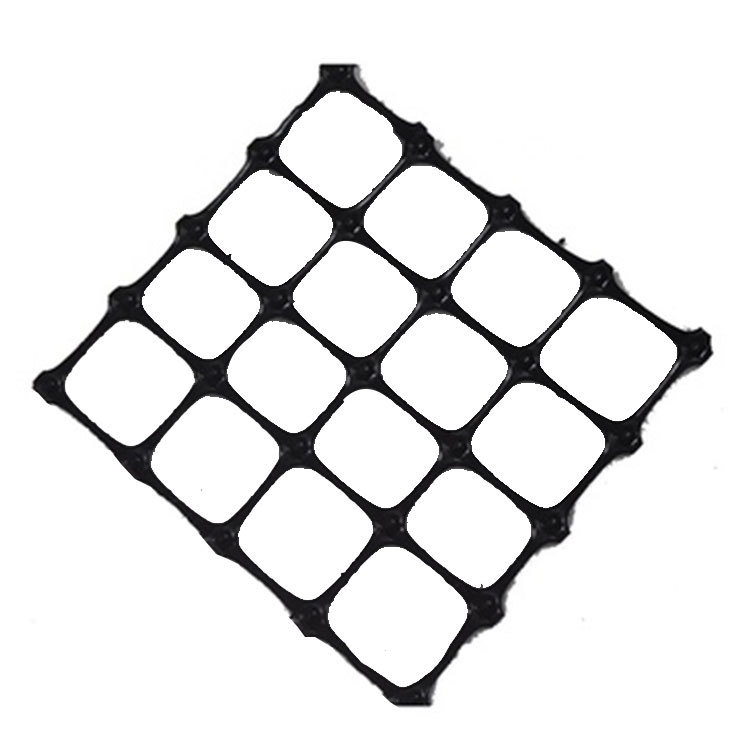

PE Net Made of Geotextile and Geonet 3D Composite Drainage Geonet

- Commodity name: PE Net Made of Geotextile and Geonet 3D Composite Drainage Geonet

- Description

-

Introduction

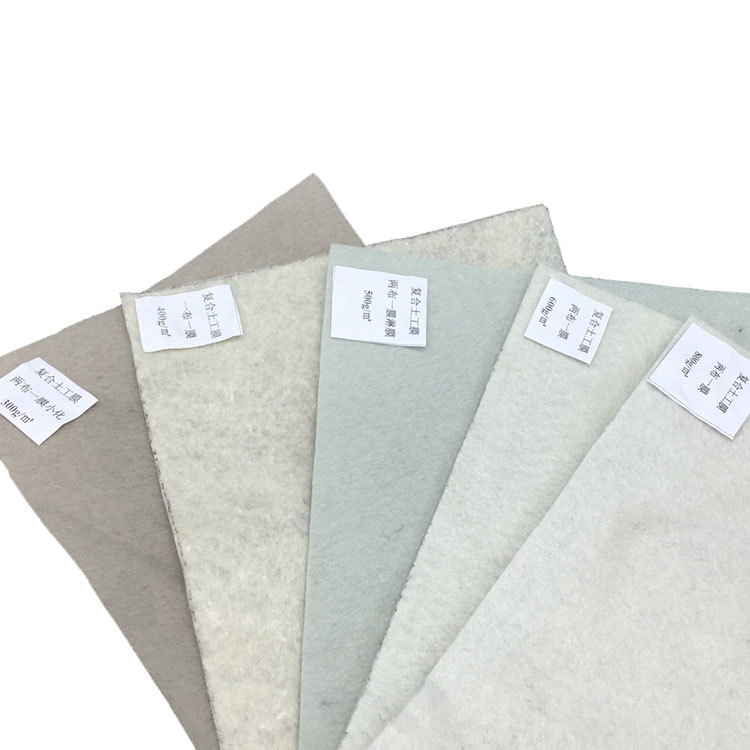

Three dimensional composite drainage community is a new kind of geosynthetics. Its shape is a three dimensional geonet core, and there are needle punched non woven geotextiles on each sides. The three dimensional geogrid core consists of a thick vertical rib and an inclined rib at the pinnacle and bottom, which can hastily drain the round water from the road. Composite geonet is a new kind drainage material. lt has three layers: third-dimensional geonet and nonwoven geotextile on each aspects Thematerial of geonet is HDPE. and the fabric of geotextile can be needle punched PET/PP nonwoven geotextile and thermal bonded non-stop filament nonwoven geotextile. It additionally has a pore upkeep system, which can block capillary water underneath excessive load. At the identical time, it can additionally play the position of isolation and basis reinforcement.

Video Showcase

Applications

- Highways: vertical edge-of-carriageway drains intercept the lateral waft of floor water. Modern fin drains limit excavation, minimize backfill portions and minimize set up time. In-slope drainage will increase geotechnical stability.

- Retaining partitions and bridge abutments: to minimize pore water strain and keep away from backfill saturation.

- Engineered landfills: with the extra requirement of long-term chemical resistance and excessive compressive strength.

- Tunnels: ground-water-seepage interception between rock face and the tunnel lining.

- Buried structures: vertical and horizontal drains for basements, culverts, auto parks, reservoirs, etc.

Working Drawing

Specifications

Pack and Ship

Packaging: Standard packaging or customer's requirements

Lead time: Within 10-15 days after receiving the deposit payment

Producing Capacity: Two 40ft Containers per week

Testing equipment

FAQ

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Certificate

Keywords:

Related Products