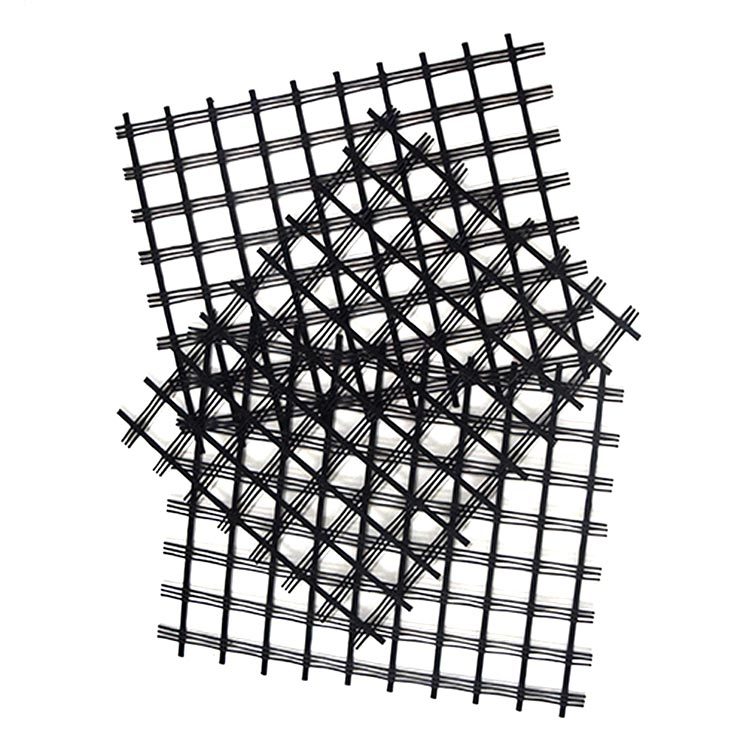

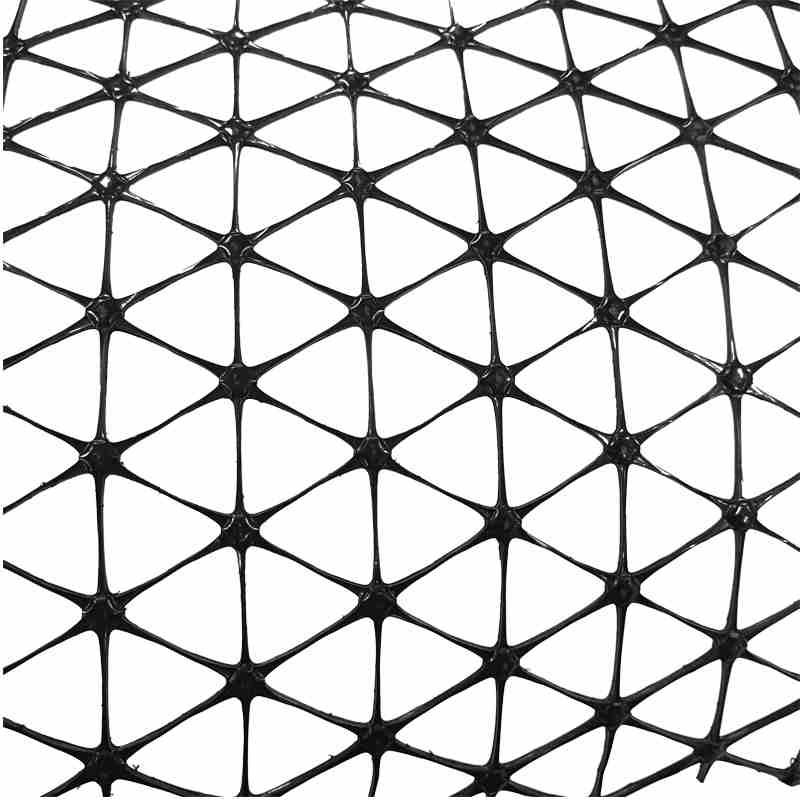

Triaxial Geogrid soil stabilization geogrid for road construction triaxial geogrid

- Commodity name: Triaxial Geogrid soil stabilization geogrid for road construction triaxial geogrid

- Description

-

Introduction

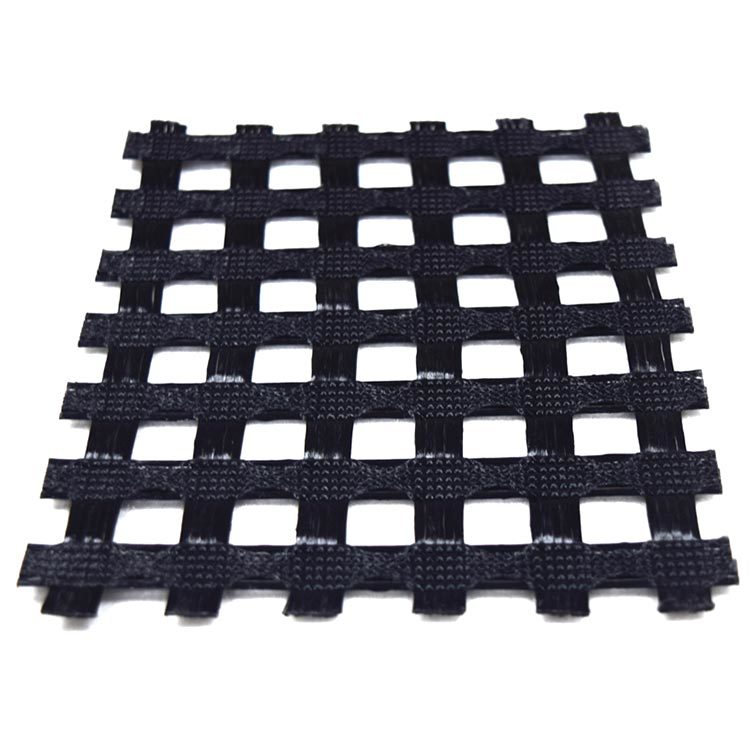

To strengthen the road, Triaxial Geogrid is used as a key element in the construction process. Triaxial Geogrid is a high-strength geosynthetic material that is designed to provide reinforcement and stabilization to the road structure. It works by distributing loads more evenly, reducing pressure on the road surface and preventing deformation or rutting.

By incorporating Triaxial Geogrid into the road construction, it helps to improve the overall performance and longevity of the road. It enhances the structural integrity and load-bearing capacity of the road, making it more durable and resistant to wear and tear.

In conclusion, the use of Triaxial Geogrid is essential in strengthening roads, ensuring they can withstand heavy traffic and harsh weather conditions for years to come.

Video Showcase

Applications

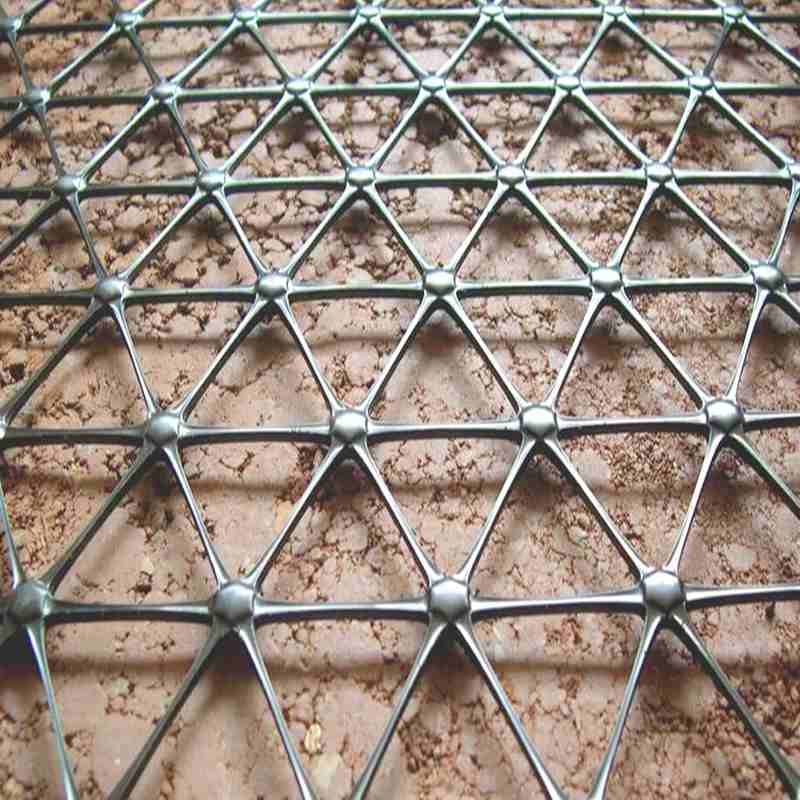

Subgrade stabilization: Triaxial geogrids are utilized to stabilize the subgrade of roadways by distributing applied loads and reducing differential settlement. They improve the load-bearing capacity of weak soils, reducing deformation and enhancing overall road performance.

Base reinforcement: Triaxial geogrids are often placed within the base course layer of roads to improve tensile strength, prevent reflective cracking, and increase structural stability. They help disperse traffic loads evenly, reducing rutting and extending the service life of the road.

Pavement rehabilitation: Triaxial geogrids are commonly used in pavement rehabilitation projects to strengthen and reinforce existing asphalt or concrete surfaces. By incorporating geogrids into the pavement layers, cracking and fatigue damage can be minimized, enhancing durability and prolonging maintenance cycles.

Preventing reflective cracking: Triaxial geogrids help mitigate the occurrence of reflective cracking, which results from the propagation of cracks from the underlying layers to the surface asphalt or concrete. By acting as a barrier and distributing imposed loads, geogrids reduce the likelihood of cracks forming and reappearing on the road surface.

Subbase reinforcement: Triaxial geogrids can be employed in subbase layers to improve load transfer and enhance the stability of road foundations. By confining aggregate materials within the geogrid structure, they increase shear strength, reduce lateral spreading, and enhance overall structural integrity.

Slope stabilization: In road construction projects involving steep embankments or road cuts, triaxial geogrids are used for slope stabilization. They provide reinforcement to prevent erosion, slippage, and slope failure, ensuring the long-term stability of roadside slopes and cut slopes.

Mechanically stabilized layers: Triaxial geogrids are integrated into mechanically stabilized layers within road construction projects to create composite structures that withstand heavy traffic loads, reduce settlement, and enhance overall pavement performance. These geogrid-reinforced layers offer enhanced tensile strength and structural stability.

Reinforced soil walls: Triaxial geogrids are also utilized in the construction of reinforced soil retaining walls along roads and highways. By reinforcing backfill soil with geogrid layers, these walls can withstand lateral earth pressure, control soil movement, and provide long-term stabilization for roadside structures.

Working Drawing

Specifications

Item

Test Method

Unit

Standard

Polymer

-

PP

Rib Middle Distance

-

mm

35

Minimum Carbon Black

ASTM D 4218

%

2

Radial Secant Stiffness at 2% Strain

ASTM D 6637

kN/m

225

Elongation

ASTM D 6637

%

13

Junction Efficiency

GRI GG2

%

96

Experimental Conditions

Temperature: 20℃

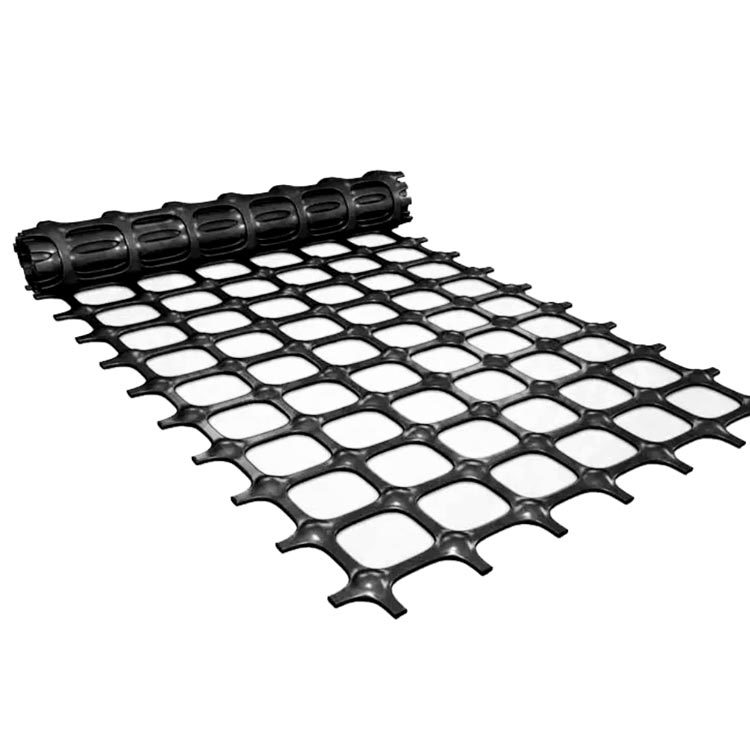

Roll Width

-

m

3.95

Roll Length

-

m

50

Note: MD = Machine Direction; TD = Transverse Direction.

(1) MD = Machine Direction; TD = Transverse Direction;

(2)Roll width can be 1m, 1.1m,1.3m,2m,2.2m or as per customized.

# Lin Yuan Geosynthetics reserves the right to change the product specifications at any time.

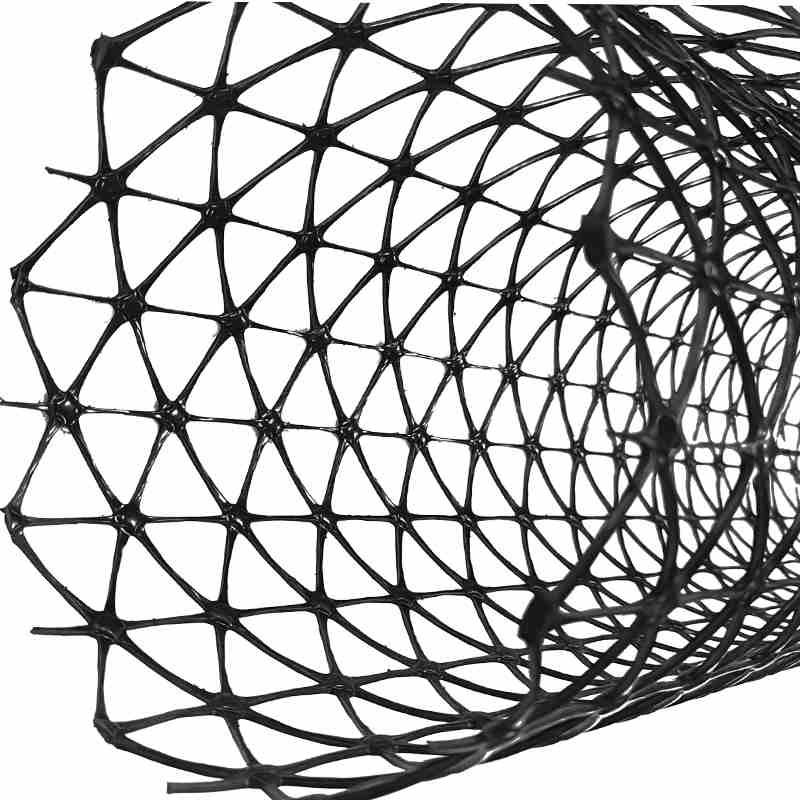

Pack and Ship

Packaging: Standard packaging or customer's requirements

Lead time: Within 10-15 days after receiving the deposit payment

Producing Capacity: Two 40ft Containers per week

Testing equipment

FAQ

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Certificate

Keywords:

Related Products